Acid waste piping is used to transport acidic or alkaline liquids that have a boiling need of around 200 degrees Fahrenheit. This type of piping should be created from acid or alkaline-resistant material with the assistance of chemical fabricators, and it is vital to develop heat-resistant seals to stop the liquid from causing pressure due to heating. There are three types. Gravity acid waste piping, Pressure acid waste piping, and Vacuum acid waste piping. They each have their own set of challenges. Gravity and pressure are much more common than vacuum. If you would like to determine which type best is for your situation then please read on.

What Is Acid Waste Pipe?

Acid waste pipes are used for the disposal of acid-containing waste streams. These can be generated from a variety of processes including chemical manufacturing, food processing, and metal finishing.

Acid waste pipes should be designed, installed, operated, and maintained according to the relevant regulations and codes of practice. They should also be able to accommodate changes in flow rate and level.

Acid waste pipes are typically made of steel or plastic, but may also be made of concrete or fiberglass-reinforced plastic (FRP). They must be able to withstand the corrosive effects of acids while being resistant to damage caused by impacts and abrasion during handling.

The design of acid waste pipes should take into account factors such as:

- Strength requirements;

- Flow characteristics;

- Environmental conditions; and

- Applicable health & safety requirements

Is Acid Waste Pipe Safe?

An acid waste pipe is used to transport acidic liquid from one location to another. It is usually made of stainless steel or plastic, and the material depends on the type of acid being transported. It is also used for transporting other types of hazardous wastes, such as toxic chemicals, radioactive materials, and more.

They can be a hazard if not properly installed and maintained. If there are leaks in the system, it could result in damage to surrounding areas and even personal injury to workers or bystanders. The size of the pipe will determine how much acid can flow through it at any given time. A small leak can cause serious problems if it occurs near flammable materials such as oil or gas because they may ignite when exposed to an acid spill. In some cases, workers who were cleaning up after an accident were burned by the acid spray when they got too close to it

Acid Waste Pipe Installation Tips

Acid waste piping is a common and important part of acid waste management. It is used in chemical plants, refineries, and other industrial facilities. Acid waste piping systems can be installed in a variety of ways, depending on how the acid is generated and the way it will be disposed of.

drainage piping systems are made up of three main parts: the generator, the acid waste piping network, and the condenser. The generator is where the acid is produced. The drainage piping system transports the acid from this point to its final destination, typically an underground storage tank or other disposal sites. The condenser receives liquid from all points along the system and processes it so that it can be safely returned to its original state without contaminating other parts of the system or harming employees who come into contact with it

There are several steps you can take to ensure that your acid waste pipe installation goes smoothly:

1) Make sure you have enough space for installation

Before starting any work on your bathroom or kitchen, make sure you have enough space for installing an acid waste pipe. If not, you may need to consider relocating some items in your cabinets and countertops before continuing with the project.

2) Plan ahead before starting the installation

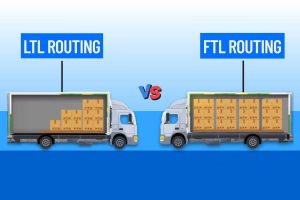

It’s important that you know exactly what kind of piping system you’re using before beginning installation work because there are several different types available today. Each has its own set of pros. Professionals in the industry often ask, “What is pigging in pipeline?“, seeking to understand the process used for cleaning or inspecting pipelines to ensure efficient operation and maintenance.

Acid Waste Pipe Replacement Tips

Acid waste pipe replacement is a process that typically involves the replacement of corroded or damaged acid waste pipes and their fittings. Acid waste pipes are typically made of copper and can be found in different industries such as chemical plants, oil refineries, mining sites, and other industrial operations.

It is used to transport wastewater and other chemicals from one place to another. Acid waste pipe systems are designed with maximum efficiency in mind so that they can handle large volumes of corrosive liquids without breaking down quickly. These pipes are also made with materials that are strong enough to withstand the harsh environment where they will be used.

The pipe has several components that make up its structure. The most important components include:

Pipes – The main component of any acid waste pipe system is its pipes. These pipes are generally made from copper or steel and they carry wastewater through the entire system by connecting all parts together. The material used for these systems depends on how corrosive the liquid being transported is since some materials may not hold up well against certain types of acids or chemicals.

Fittings – piping also contains fittings that help connect each piece of pipe together properly so that there are no leaks or gaps between them allowing for proper

Conclusion:

acid waste piping is designed to deal with acidic waste, mostly from the food processing industry. There are two basic types of acid waste piping: autoclavable and non-autoclavable. Autoclavable acid waste piping has an acid-proof lining which means it is suitable for highly corrosive acids such as hydrochloric, sulphuric, and phosphoric acid. If this type of acidic waste needs to be carried over a long distance then non-autoclavable Acid Waste Piping is recommended.