Whether you’re a business owner looking to purchase a laser cutter for your shop or you’re a DIY enthusiast looking for a way to cut out wood, acrylic, or fabric, there are many different laser cutters on the market. But which one should you choose?

Wood

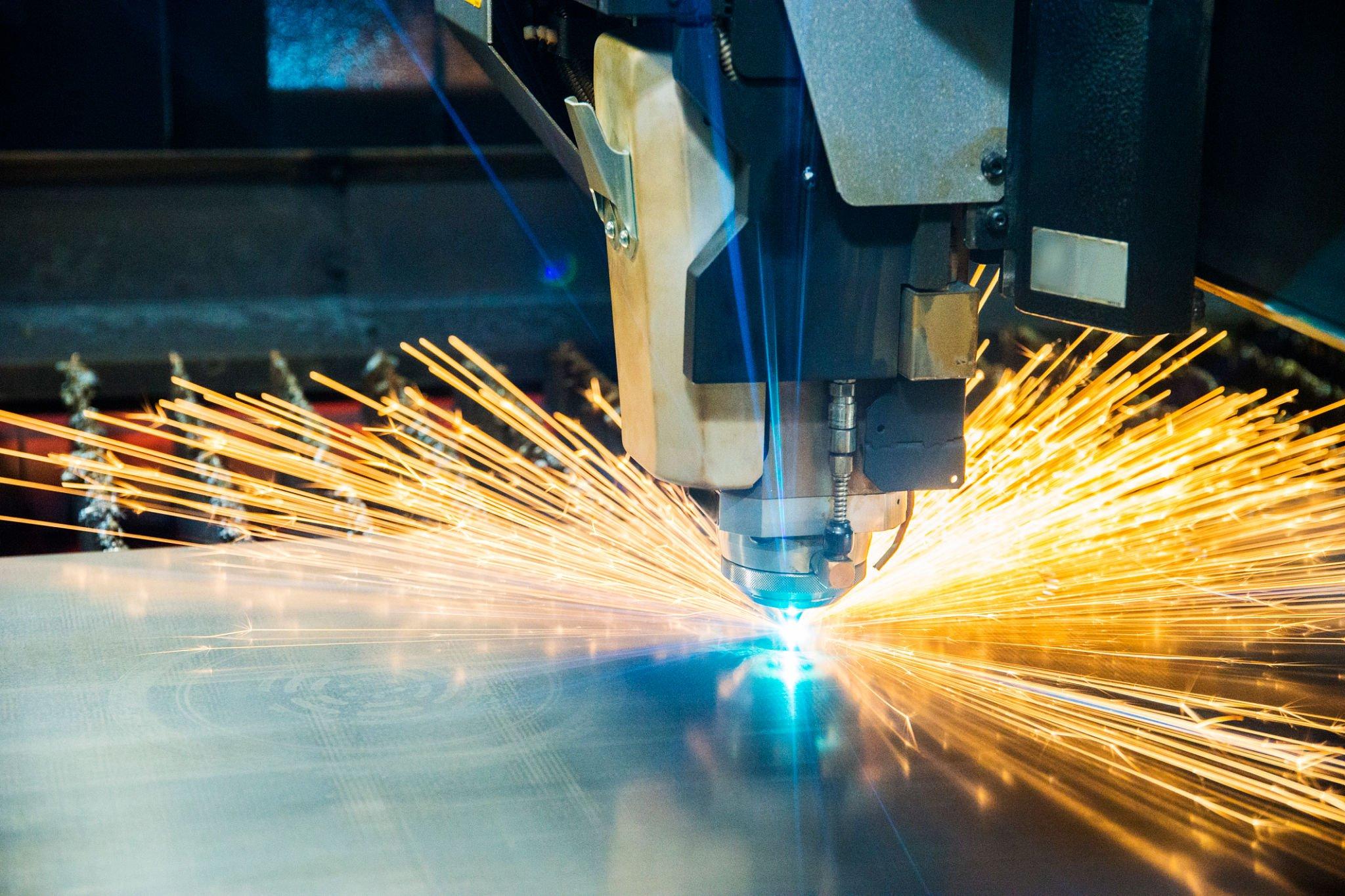

Whether you’re looking to create an intricate design or etch a simple design into a piece of wood, a laser cutter can be the answer. These machines have the ability to cut wood, paper, and even some plastics. These machines are also known for their speed and accuracy. They’re perfect for any level of user.

Before getting started, it’s important to understand what type of wood you’re working with. While most laser cutters are capable of cutting a wide range of materials, the best one for your needs is one that can handle wood at a decent thickness. You should start out with wood that’s about 3 millimeters thick. This is about the same thickness as a standard 1/10″ piece of wood.

If you’re looking to cut something that’s thicker than 3 millimeters, you’ll want to look for a laser cutter with a longer focal length. A longer focal length can help you get a better cut, and will also increase your speed.

The research record consists of unique segments by means of the vicinity (United States of America), via manufacturers, by using Type, and with the aid of Application. Each type affords facts approximately the manufacturing in the course of the forecast length of 2021 to 2028. By Application section also affords intake at some point in the forecast period of 2022 to 2028. Understanding the segments enables figuring out the significance of various factors that use resources in the market increase.

Acrylic

Using a NOVA laser cutter is a great way to cut acrylic. These machines are highly efficient and are designed to save you a lot of time. They feature clean no-contact technology and can cut most brands of acrylic.

The process of cutting acrylic using a laser machine is quite simple. The laser cuts the material, leaving sharp edges. The acrylic is then polished to ensure a clear finish. The process is fast and efficient and will result in a quality end product.

Acrylic comes in a variety of different colors and textures. In addition, it is inexpensive. The material can be cut and engraved in many different ways. The process is also relatively safe.

A laser-cutting machine is an expensive investment, and you need to consider some key factors before you make a purchase. Aside from the power and speed settings, you also need to consider the brand and the technical features of the machine.

Fabric

Using a NOVA laser cutter, you can cut fabric with precision. It is a cutting machine that uses laser technology at every stage of the process. This enables you to cut intricate designs and produce higher-quality products.

The first step is to set up the laser cutter. You will need a few parts, including the laser head, optics, mechanics, and a controller. You will also need a ventilation system. It is important to avoid overheating the glass.

Next, you will need to set the speed and power of the laser. This will vary depending on the fabric you are cutting. For thicker materials, you may need to increase the laser power.

You can also use a dual-head laser cutter to achieve faster-cutting productivity. A single-head machine can work well for garment layout, but it is not optimal for cutting large pieces of material.

Cermark

Using a NOVA laser cutter is one of the best ways to get clean cuts and a good resolution on the material. They are used in a wide range of industries, including industrial settings, advertising, and medical devices. These machines can cut materials such as wood, stone, and metal. They are easy to use and relatively inexpensive. They are also popular in the DIY market.

Before you begin cutting with a laser cutter, you need to determine what type of material to cut. Some plastics are not good to cut, and others may cause a fire. You should also be aware that acrylics contain fumes. These can be toxic.

Polycarbonate is a poor choice for cutting. It absorbs infrared radiation very well and creates a stringy cloud of soot that can mess up your optics.

Laser Cutter NOVA 51

NOVA laser cutter 51 is a powerful machine that can cut a wide range of materials. It features a powerful 130W CO2 laser tube that can cut thin materials. It can also mark ceramics, glass, and some metals.

It has a motorized work table that includes an auto-sensing rotary port. The motorized table reduces reflection on the laser.

The laser also has a water cooling system. It is equipped with a nozzle that is adjustable to different focal distance setups. The nozzle also features an auto-shutdown mechanism. The laser can also work in raster mode. The nozzle also has a built-in ventilation system that expels smoke.

The laser engraver is equipped with a hybrid servo motor. It also has an intuitive display panel that makes the control process more user-friendly.